Our Zinc Alloy Pressure Die Casting Department is a modern and highly automated production center, equipped with the latest technologies that ensure the highest quality and precision of castings. We have an advanced machine park consisting of 15 die-casting machines from renowned manufacturers such as FRECH and AGRATI, enabling us to meet even the most demanding orders.

Technical Specifications:

- Machine clamping force: 20 – 200T

- Maximum injection weight: 2200 g

- Automated casting cells: 2 stations equipped with KUKA KR 16F six-axis robots, enabling automatic part removal and insert placement in molds

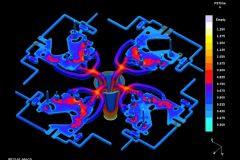

- FLOW 3D Cast simulation program: supports tool design and eliminates potential casting defects

Thanks to advanced automation, including KUKA robots, our foundry ensures not only precision and repeatability in production but also efficiency and process optimization. We offer comprehensive zinc alloy pressure die casting services, tailored to our clients’ needs, with a guarantee of the highest quality and reliability.