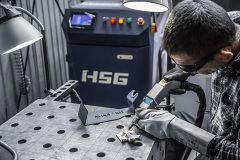

Our Precision Welding Department is a modern and highly automated technology center, ensuring the highest quality and precision in the fabrication of welded structures. We have an advanced machine park equipped with devices from renowned manufacturers, enabling us to handle even the most demanding projects.

Technical Specifications:

- Machine clamping force: 20 – 200T, allowing for precise control of the welding process and adjustment to the specific needs of each project.

- Maximum injection weight: 2200 g, giving us the capability to work with a variety of materials and produce complex, heavy components.

- Automated production cells: 2 stations equipped with KUKA KR 16F six-axis robots, providing automatic part removal and insert placement in molds, enhancing the efficiency and precision of the processes.

- Welding process simulation program: FLOW 3D Cast, supporting tool design and eliminating potential defects, ensuring the highest quality of welds.

Thanks to advanced automation, including KUKA robots, our Precision Welding Department ensures not only accuracy and repeatability in production but also process optimization, leading to increased efficiency and time savings. We offer comprehensive welding services tailored to the individual needs of our clients, with a guarantee of reliability and the highest quality standards.